TECHNOLOGY

Advanced Lens Technology

AddOptics has pioneered a revolutionary approach to optical manufacturing that combines precision engineering with proven material science. Our proprietary optical moulding process represents a significant advancement in lens production technology.

OUR APPROACH

Design for Manufacturing

Traditional lens manufacturing involves complex, multi-step processes with significant limitations in customization. The AddOptics technology platform transforms this paradigm by enabling true mass customization of optical components.

Our proprietary Design for Manufacturing (DFM) technology creates custom moulds for each customer, enabling unprecedented personalization at scale. The precision-engineered moulds allow us to manufacture unique lenses cost-competitively, maintaining quality while eliminating the traditional trade-off between customization and affordability.

Mass Customization

Each lens can be individually designed and produced with unique specifications without the prohibitive costs typically associated with custom optics.

Ambient Processing

Manufacturing under ambient pressure and low-temperature conditions preserves component integrity while ensuring consistent optical quality.

Standard Compatibility

Compatible with standard ophthalmic polymers while achieving precision that exceeds conventional manufacturing capabilities.

VISION CORRECTION

Full Prescription Compatibility

Our technology delivers the same refractive correction capabilities found in commercially available lenses from opticians, maintaining compatibility with standard prescriptions and vision correction needs.

Patients can seamlessly transition to AddOptics lenses while receiving identical optical performance for conditions like myopia, hyperopia, astigmatism, and presbyopia that they would expect from traditional eyewear providers.

MATERIALS

Material Portfolio

Our materials range from standard optical resin for pre-production and lower diopters to high-refractive options for stronger prescriptions. All materials offer excellent clarity, color rendering, and impact resistance with low curing temperatures.

Standard Optical Resin

Ideal for pre-production and lower diopter requirements

Mid-Index Material

Balanced option for moderate prescription strengths

High-Refractive Index

For stronger prescriptions requiring thinner profiles

CASE STUDIES

Proven Technology in Action

Explore our demonstrated capabilities across thin film embedding, waveguide integration, and component encapsulation.

THIN FILM EMBEDDING

Fully Embedded Thin Films

E-chromic dimming technology fully embedded within the lens structure, enabling comfortable vision in bright settings with fast switching times.

DIRECT ON WAVEGUIDE CASTING

Reflective Waveguide Push-Pull & RX

Direct casting onto reflective waveguides with integrated prescription correction, combining display functionality with vision correction in a single optical element.

AIRGAPPED WAVEGUIDE ENCAPSULATION

Diffractive Waveguide Embedding

Advanced airgapped encapsulation technique for diffractive waveguides, protecting delicate optical surfaces while maintaining optical performance.

COMPONENT INTEGRATION

Embedded Electronics

Embedded electronics in worlds most thin and lightweight eyepieces, integrating eye-tracking and illumination circuits directly into the lens stack.

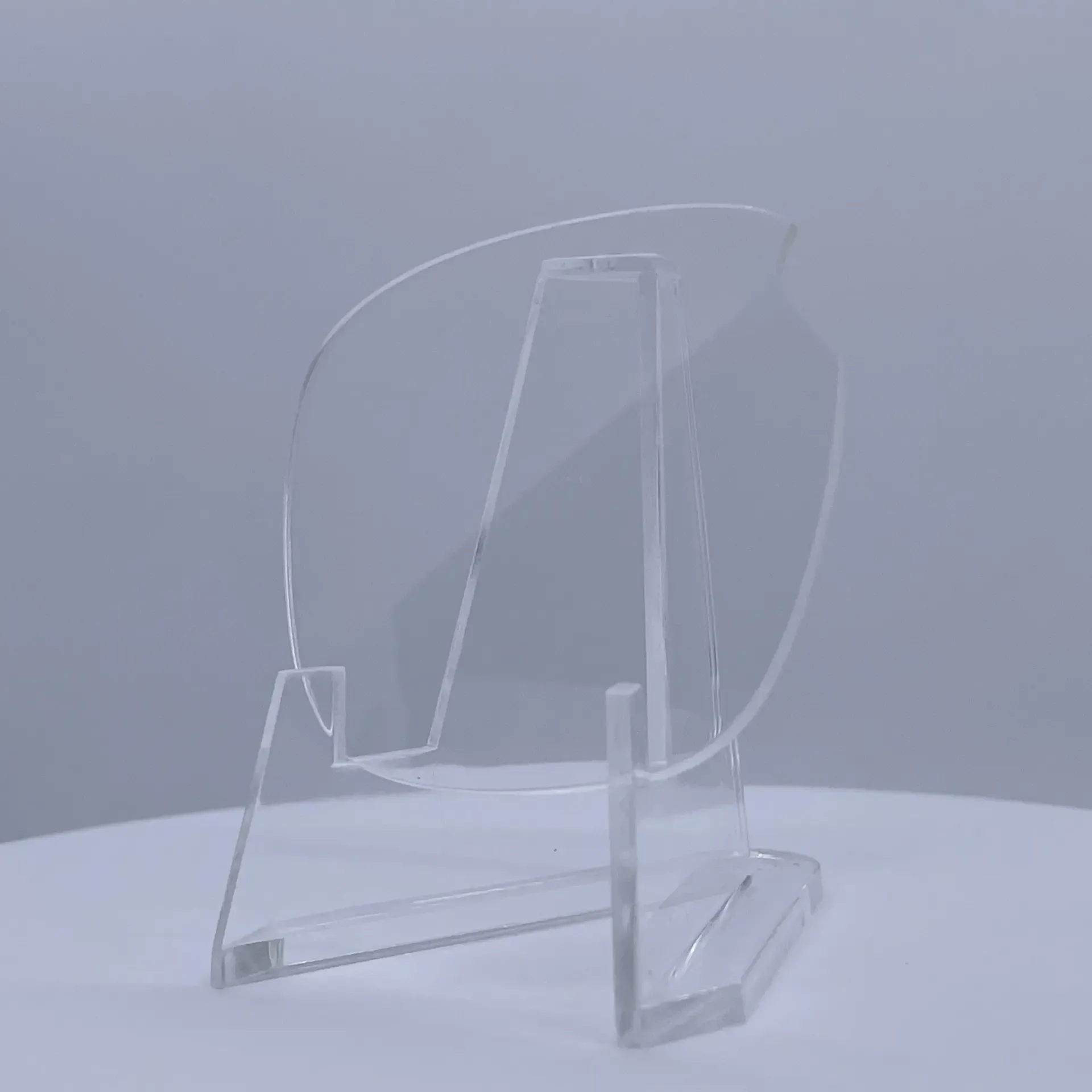

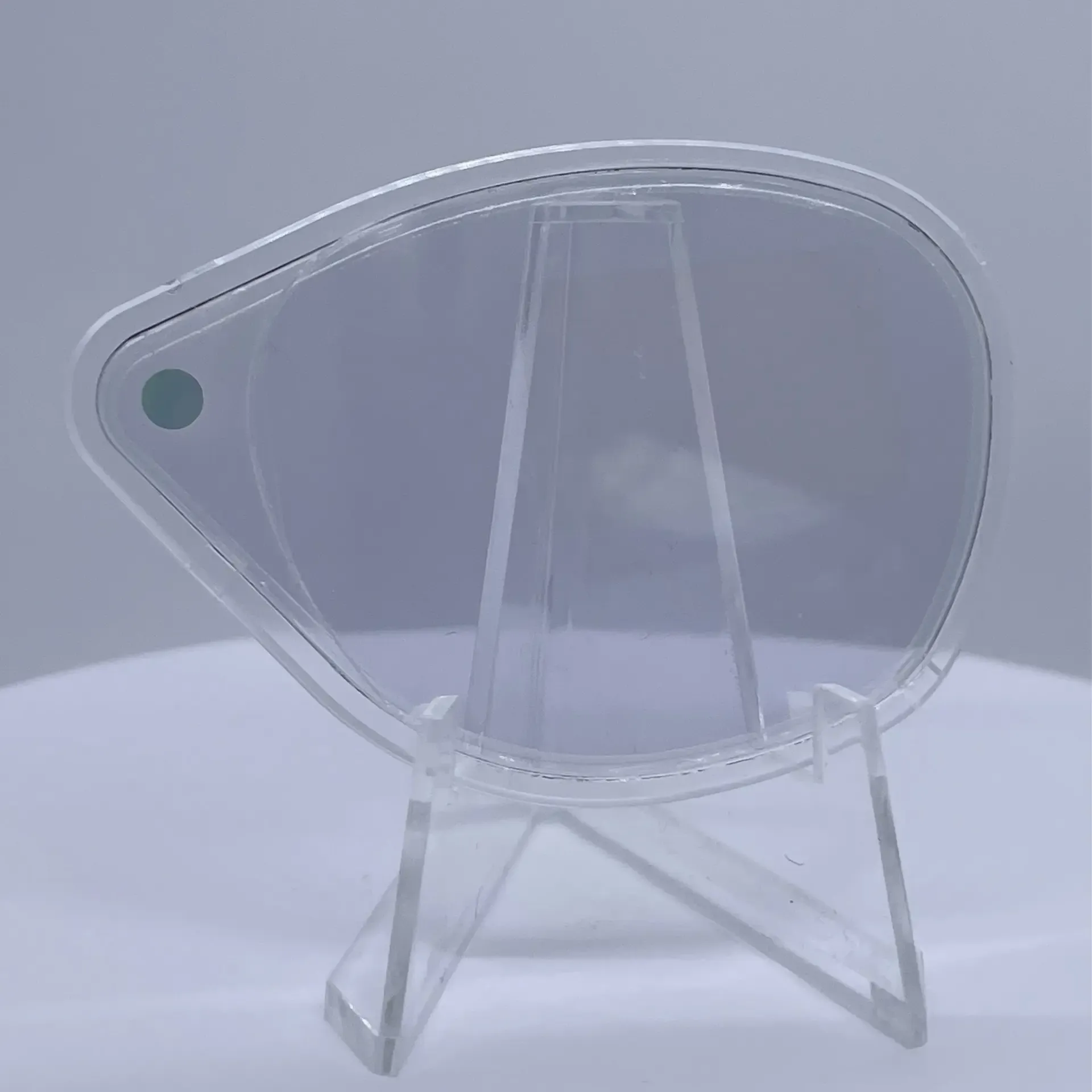

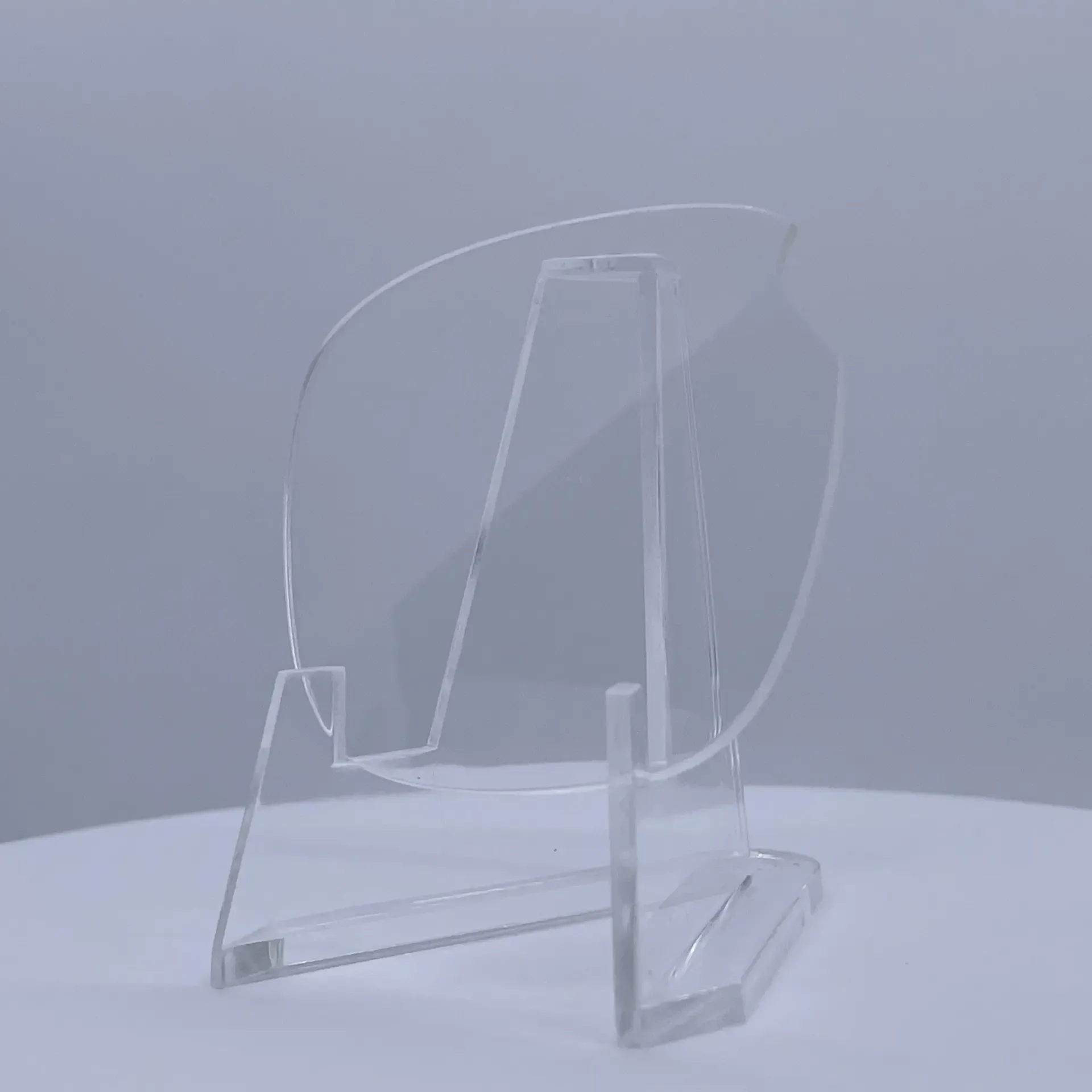

SUB-MM PRESCRIPTION ELEMENT

Ultra-thin RX-plano

Sub-millimeter prescription correction elements designed as glue-on attachments, enabling vision correction without adding bulk to existing devices.

Ready to integrate our technology?

Our team is ready to discuss how AddOptics lens technology can enable your next-generation smart eyewear product.

Get in touch